Extramet Grades

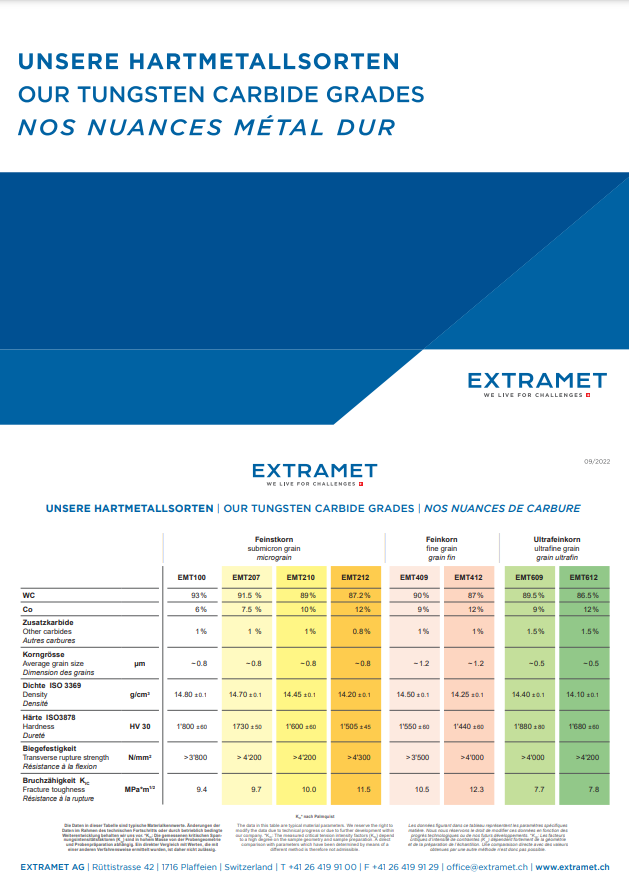

Our proprietary grades are produced on an application specific basis. All materials are traceable to the production lots and manufactured in accordance with international health, safety, and quality standards.

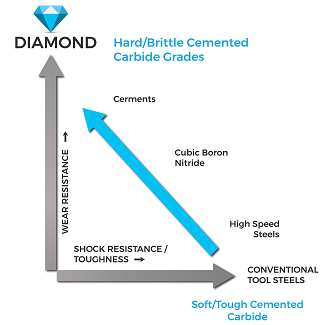

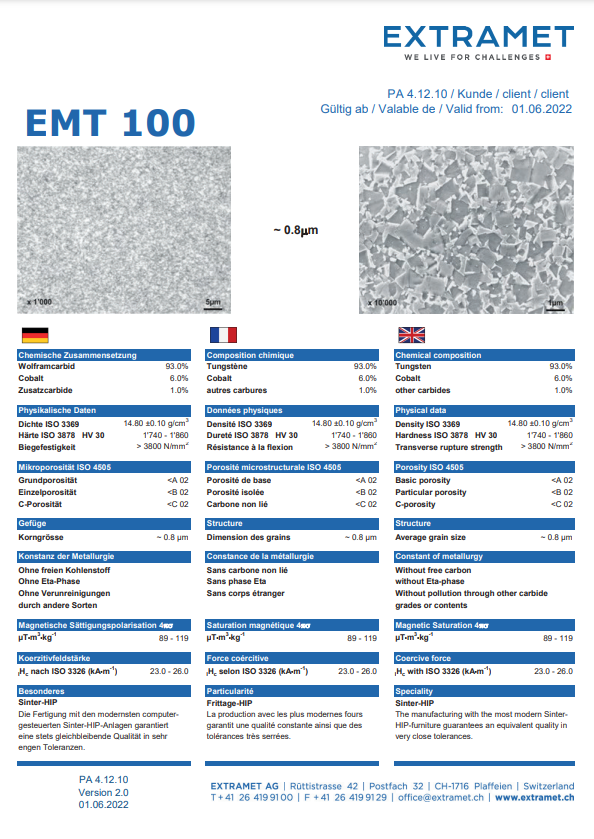

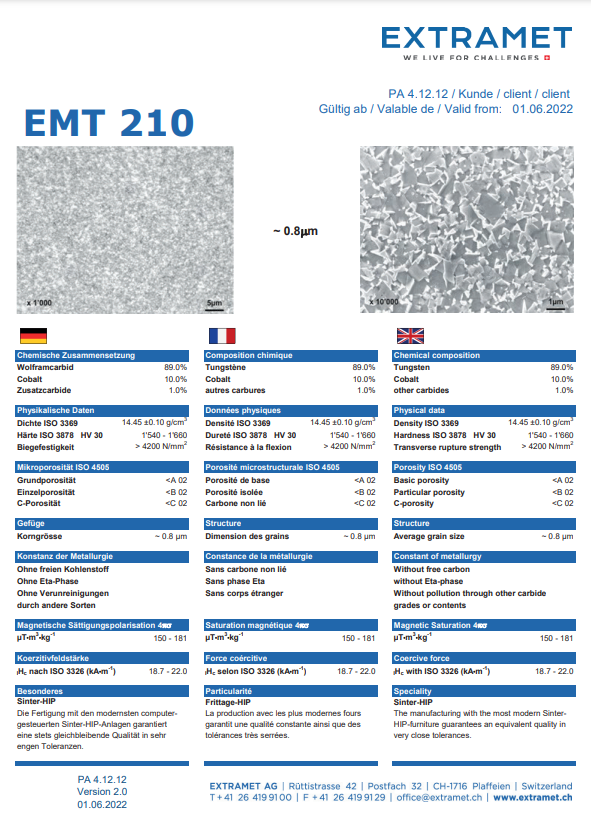

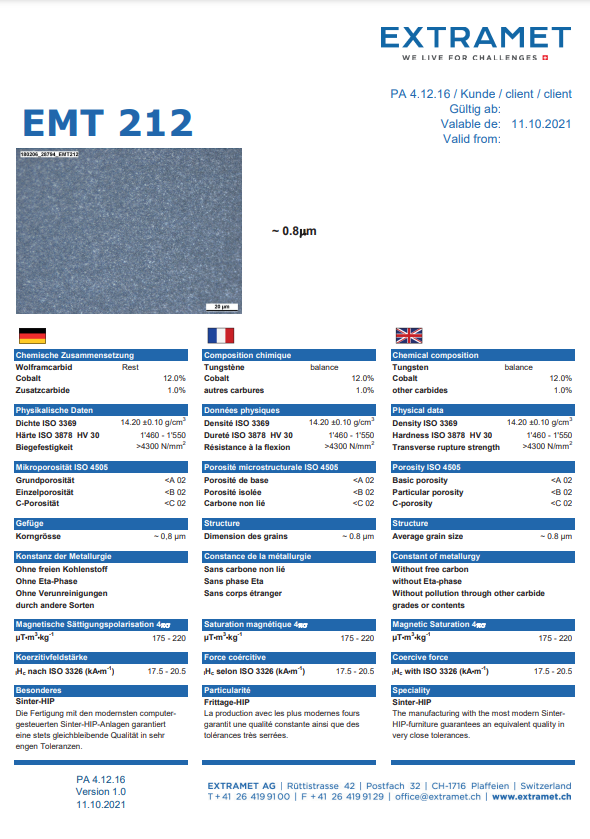

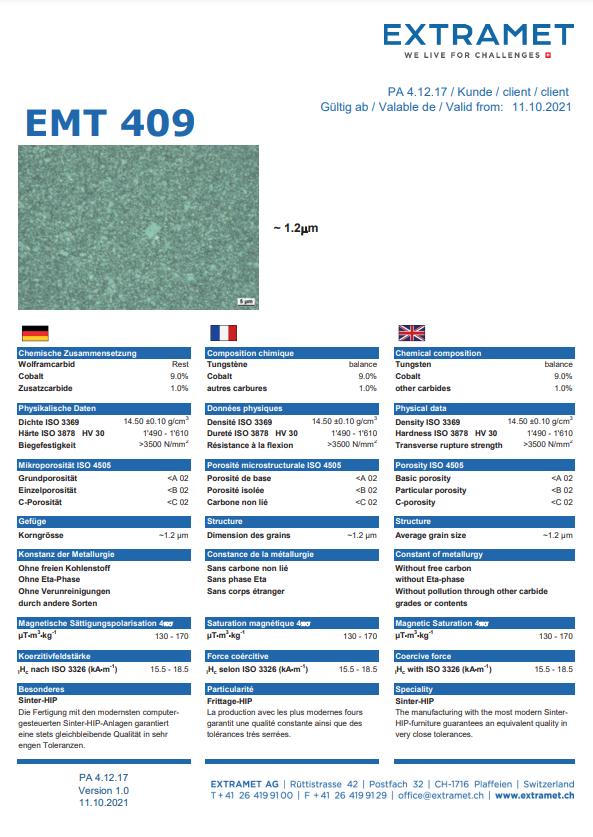

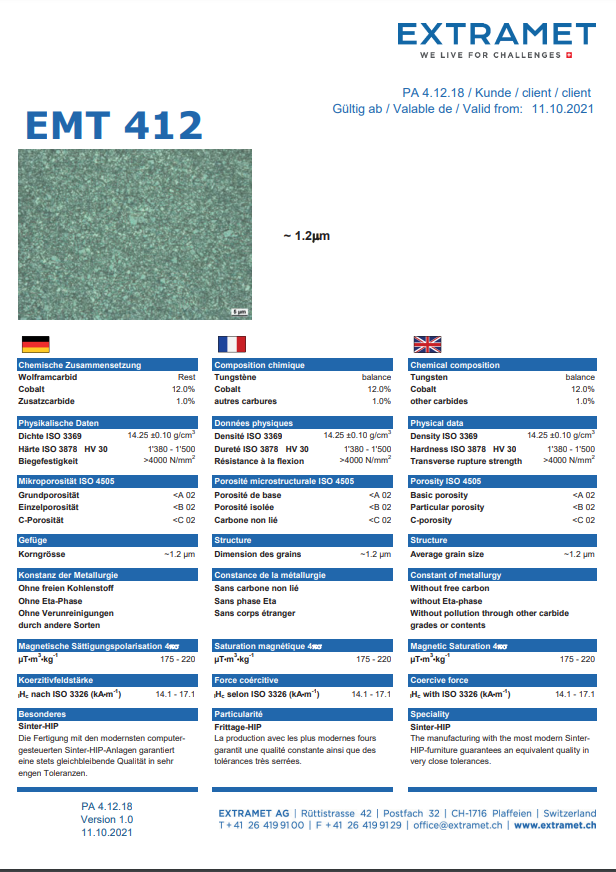

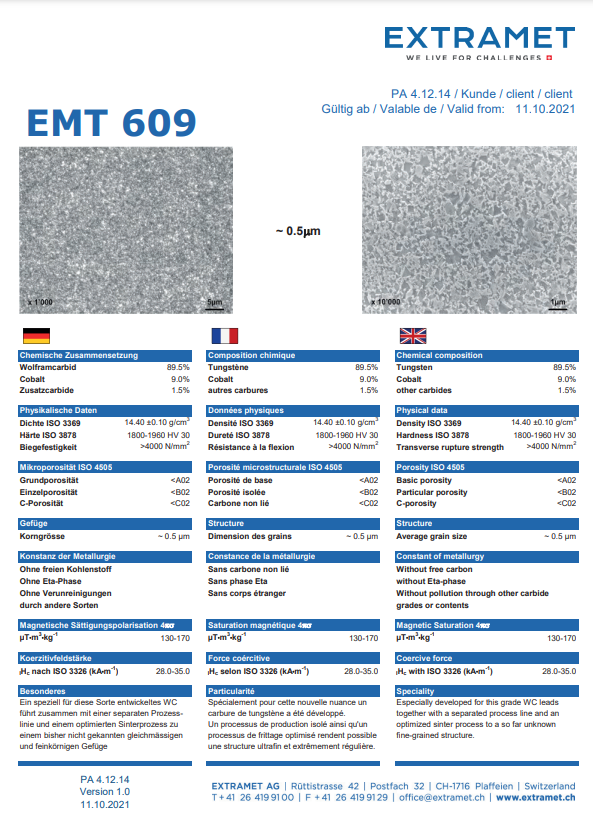

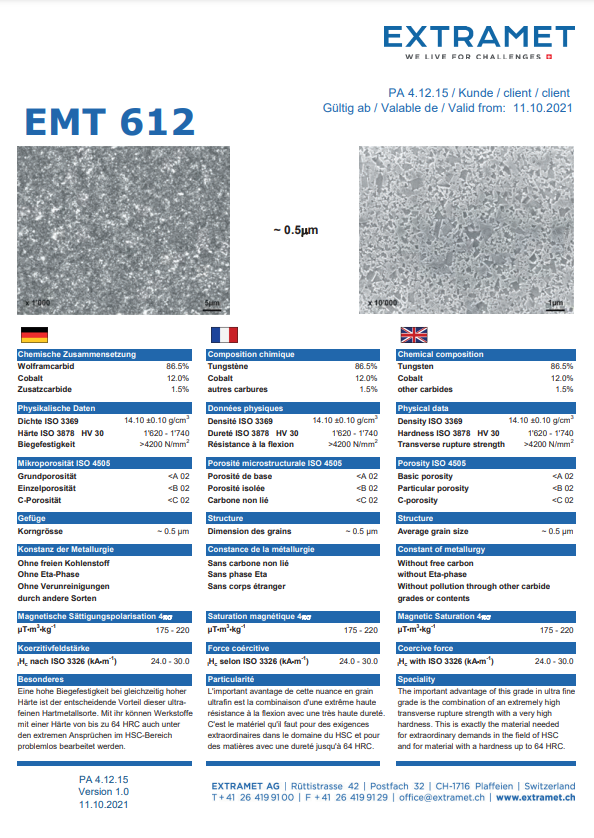

While there are many different grades of Tungsten Carbide available containing various additives for a variety of applications, on the most basic level the primary properties of any given grade (Hardness and Toughness) are determined by the ratio of Tungsten Carbide to Cobalt. In general, a lower percentage of Cobalt will produce a harder, more brittle material while a higher percentage will produce a tougher, less wear resistant material.

Selecting Grades

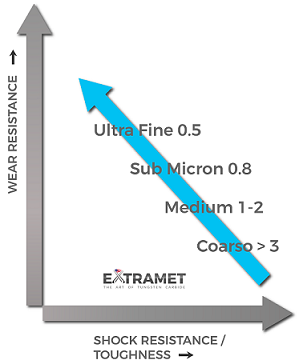

There are over a dozen different grades of Tungsten Carbide. When evaluating equivalents of Tungsten Carbide grades the important criteria is to specify two of three factors; binder content, hardness or grain size. Balance must be made between wear resistance and impact resistance.

What is Tungsten Carbide?

Tungsten carbide is a homogenous mixture of tungsten carbide grains in a tough cobalt binder matrix. The carbide grains are fused into a solid matrix of cobalt metals. The metal carbide’s grains are “cemented” in the binder metal’s matrix. The fusion process is called liquid phase sintering, or sinter for short.