ON-SITE CAPABILITIES

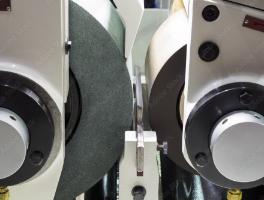

Centerless

Grinding

We will grind our stock or yours (tolerances +/- 0.0001″).

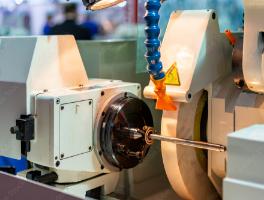

CNC Cylindrical Grinding

Our CNC cylindrical grinding operations deliver exact tolerances time and time again.

Laser

Etching

A laser etcher offers added versatility.

Surface

Grinding

We are equipped to process products up to 36″ in length.

INDUSTRY SOLUTIONS

Tungsten Carbide is utilized in all manufacturing industries across the globe

OUR PRODUCTS

Extramet offers an extensive range of grades to better suit any application requiring wear and/or corrosion resistance

View Grades

Rod & Grinding Estimator for ground parts from our standard stock

View Estimator

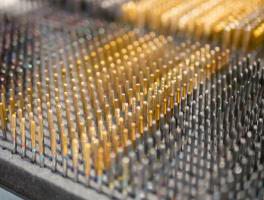

True in form and dimensions, Consistent in quality. Our blanks are used in Plant and mechanical engineering · Tool, die and mold making · Shaping, Drawing, and Sizing Tools. Extramet’s raw materials are not sourced from China.

View Product

Maximum edge stability and perfect surface finishing ensure excellent cutting results. Paper and printing industries, Sheet metal-processing industry · Plastics industry.

View Product

Improved safety, higher efficiency, better results. These components are used in General wear protection in many different sectors and industries. Parts are produced according to customer specifications.

View ProductOUR STORY

Sustainability, performance, and reliability are the three principals we live by here at Extramet. Our philosophies, combined with our place on the supply curve, guarantee constant and consistent supply now and in the years to come.

Emergency Delivery

Available

Extensive Inventory

Quick Delivery

Quality Products And

Support