Extramet Products, LLC has been producing high-quality tungsten carbide components for industrial applications for decades. The company has earned a reputation for precision, durability, and consistent performance across a wide range of industries. At Extramet, every component, from tungsten carbide rods to blanks and pins, is manufactured to meet exacting standards and engineered to deliver reliable results under demanding conditions.

Tungsten carbide is recognized for its hardness and wear resistance, making it an ideal material for cutting tools, high-stress wear parts, and precision components. Components made from tungsten carbide maintain performance over long periods, which reduces downtime, increases productivity, and provides a return on investment for industrial operations.

Extramet focuses on quality and reliability in all stages of production. Our ISO 9001:2015-certified facilities guarantee consistent manufacturing processes. The company also emphasizes sustainable sourcing practices and maintains a stable supply chain, giving customers confidence in the availability of tungsten carbide rods, blanks, and pins when needed.

Raw Materials

Extramet keeps its raw materials to the highest standards in the industry. The company emphasizes performance, reliability, and long-term supply consistency. By controlling the sourcing and production of tungsten carbide rods, Extramet maintains a supply that avoids fluctuations caused by external suppliers. The company does not source its raw materials from China, which helps maintain consistent chemical composition and physical properties.

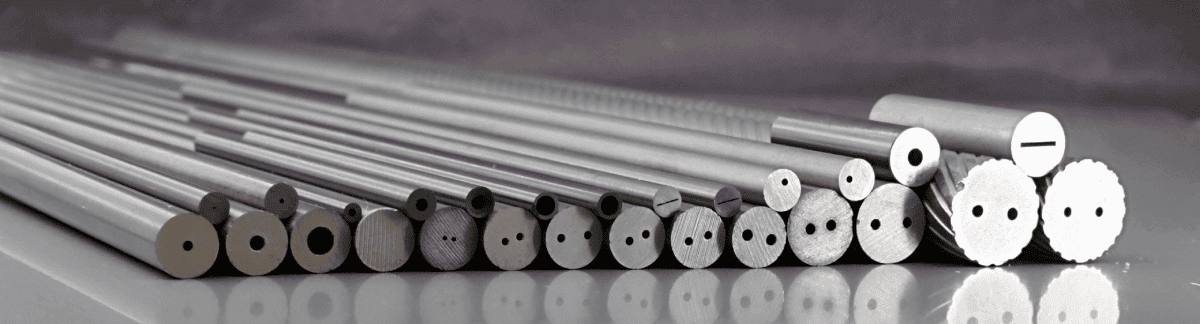

Tungsten Carbide Rods

Tungsten carbide rods are available in a variety of sizes and diameters. These rods form the basis for many industrial tools and wear components. They are used in tool manufacturing, shaping, drawing, and sizing tools, where precise dimensions and uniform hardness are critical. The hardness of tungsten carbide rods guarantees they resist wear and retain their shape even under high-stress conditions.

Each rod undergoes thorough inspection for density, hardness, and surface finish. Extramet’s quality assurance ensures that every rod meets stringent industry standards. These rods are ideal for operations requiring durability, consistent performance, and resistance to abrasive or corrosive environments.

Cutting Tool Blanks

Cutting tool blanks from Extramet are manufactured to deliver precise dimensions and consistent quality. Blanks are produced with low grinding excess, which improves surface finish and reduces post-processing time. These blanks are used as raw components for tools in industries including paper processing, sheet metal fabrication, plastics manufacturing, and printing.

Tungsten Carbide Blanks

Extramet produces both finished and semi-finished tungsten carbide blanks according to customer specifications. These blanks offer maximum edge stability and maintain sharpness through extended use. The precision of these blanks ensures that cutting operations remain efficient and predictable, reducing waste and increasing the lifespan of the tools.

The company offers a range of grades, each suited for specific cutting applications. Hardness, toughness, and wear resistance are optimized for the intended use, whether the blank will be used in fine cutting or heavy-duty machining operations.

Customer specifications can be accommodated with custom dimensions, shapes, and grades. Extramet supports high-precision CNC and grinding operations to produce blanks that fit the exact needs of the manufacturing process. Semi-finished blanks allow further finishing by the customer while still providing a reliable and uniform starting point.

Engineered Wear Parts

Engineered wear parts are designed to function under high stress and demanding operating conditions. Extramet produces components intended for mechanical engineering, plant machinery, and other industrial sectors where reliability is essential.

Tungsten Carbide Pins

Tungsten carbide pins are widely used in applications requiring high wear resistance and precision. Pins can be made in a variety of shapes and sizes, including cylindrical, tapered, or custom geometries, depending on the requirements of the machine or assembly. These pins are ideal for bearings, dies, molds, and other parts that experience repetitive mechanical stress.

The durability of tungsten carbide pins provides consistent performance and reduces the frequency of replacement. They maintain dimensional stability under load and resist deformation, making them suitable for applications where long-term reliability is critical.

Applications Across Industries:

- Oil & Gas: Components endure high-pressure environments, abrasive fluids, and extreme temperatures.

- Aerospace and Automotive: Pins are used in precise assemblies, ensuring smooth operation and reliability.

- Food Packaging and Medical Equipment: High-quality pins contribute to safe and efficient operations, with material properties that meet hygiene and regulatory requirements.

Extramet uses CNC grinding, centerless grinding, and laser etching to produce pins with strict tolerances. Dimensional accuracy and surface finish are carefully controlled to meet customer specifications. These capabilities allow the company to supply components for critical applications where failure is not an option.

Why Choose Extramet Products

Extramet Products focuses on consistent quality, reliable supply, and expertise in tungsten carbide manufacturing. Every rod, blank, and pin is inspected and tested to meet strict standards. The combination of high-quality raw materials, precision manufacturing, and industry experience allows Extramet to deliver components that provide long-term performance and reliability.

Customers benefit from a dependable supply of tungsten carbide components, backed by technical support and engineering knowledge. Extramet’s experience guarantees that products meet specific requirements, whether used in cutting tools, wear parts, or complex assemblies.

Contact our team today to discuss your requirements and discover how our products can enhance your operations. Partner with Extramet for components you can trust!