The Foundation of Performance

At Extramet Products, we believe that you can’t build a superior tool from inferior material. That’s why raw materials aren’t just an “input” for us—they are the starting point of our promise to you.

Whether you are drilling through bedrock or machining aerospace components, the consistency of our tungsten carbide defines your success. We prioritize purity and precision so you can prioritize performance.

Our Quality Commitment

Reliability starts at the source. We place a strict emphasis on purity, consistency, and traceability. By maintaining responsible supply chains and avoiding questionable sources, we ensure that every grain of powder meets our rigorous standards.

This isn’t just about checking a box for our ISO 9001 certification—it’s about ensuring that when you order from Extramet, you get the exact same high-quality material, batch after batch, year after year.

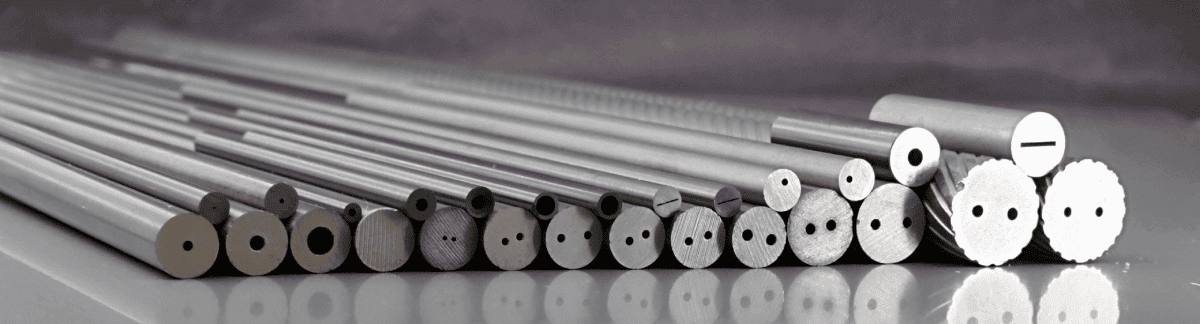

Tungsten Carbide Blanks

Our pre-formed blanks are the canvas for your tools. Designed to shorten your production time, they provide a high-quality foundation for dies, wear parts, and cutting tools.

Customers rely on our blanks because they are consistent. The uniform hardness and durability mean you can push them harder in cutting, molding, and forming environments without worrying about material failure.

Tungsten Carbide Pins

Small but mighty, our pins are essential for alignment systems and high-load mechanical assemblies. Used heavily in oil & gas and mining, these components are built to retain their dimensional accuracy even in the harshest, grittiest operating environments.

From Powder to Product

Tungsten Carbide Rods

Rods are the backbone of the precision tooling industry. They become the end mills, drills, and reamers that shape our world.

Our rods are engineered for resistance. Whether you are machining titanium for an aircraft or steel for an automotive engine, our rods maintain their cutting precision over extended cycles, withstanding extreme heat and wear.

Engineered Grades for Specific Needs

6% Tungsten Carbide

Best for: Nonferrous metals, plastics, and composites.

This grade is the sprinter of our lineup. It offers high hardness and cutting efficiency, making it perfect for high-speed cutting where precision and tool life are the top priorities.

10% Tungsten Carbide

Best for: Hardened steels, high-alloy metals, and high-stress environments.

This grade is the heavyweight lifter. With greater toughness and impact resistance, it shines in the energy and oil & gas sectors where tools face extreme stress and shock.

View our full list of Tungsten Carbide Grades here.

Why Choose Extramet Raw Materials?

From the specific cobalt content to the final dimensional check, we give you a consistent foundation. When you start with Extramet, you start with certainty.