Why Tungsten Carbide Products?

Tungsten carbide step blank products come with several major benefits:

- Enhanced accuracy: Due to its high hardness and wear resistance, tungsten carbide is ideal for precision machining processes. This allows for tight tolerances and improved accuracy in the final product.

- Reduced waste: With its high strength and durability, tungsten carbide can withstand more stress and pressure during machining processes. This means less material is lost during production, resulting in reduced waste and cost savings.

- Longer lifespan: Tungsten carbide products have a longer lifespan compared to other materials such as steel or aluminum. This makes it a cost-effective choice for long-term use.

- Improved production processes: Tungsten carbide is known for its high thermal conductivity and low coefficient of friction, making it ideal for applications such as cutting tools. This not only improves the efficiency of production processes, but also results in a smoother finished product.

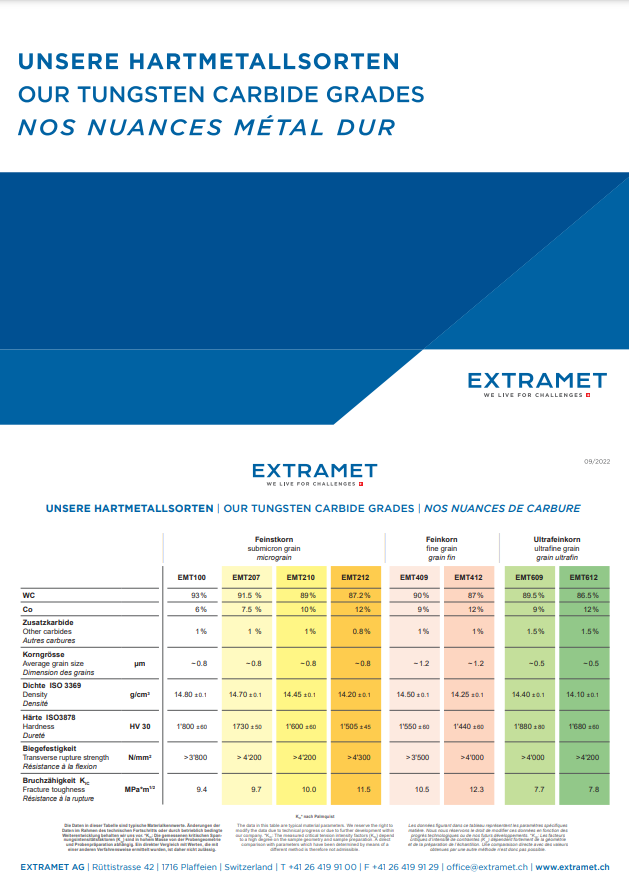

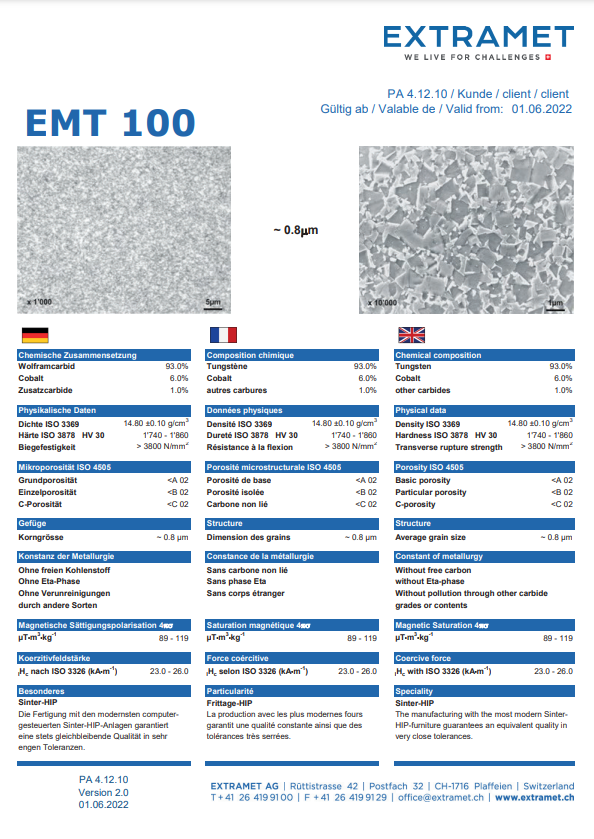

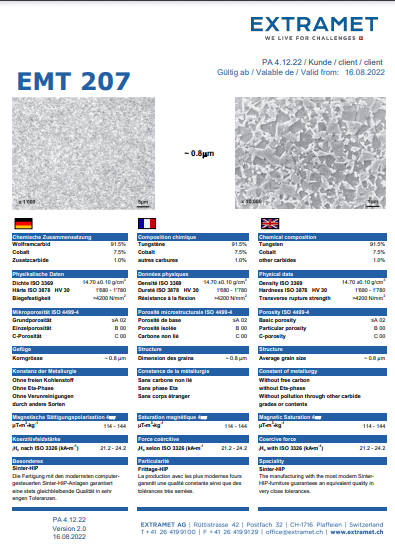

Quality 6% Tungsten Carbide Grade Materials

As one of the lowest tungsten carbide content levels among different tungsten carbide grades, the 6% tungsten carbide grade is highly sought after for its superior quality and performance. This grade is made with a mixture of 94% cobalt and 6% tungsten carbide, providing a balance between strength and hardness.

Some of the key benefits of using 6% tungsten carbide grade materials include:

- Enhanced wear resistance: Due to its high hardness, this grade provides excellent resistance against wear and tear. This makes it suitable for use in applications that involve high levels of abrasion or impact.

- Improved strength: The addition of cobalt in this grade enhances its overall strength, making it more durable and able to withstand heavy loads and extreme conditions.

- High temperature resistance: Tungsten carbide has a high melting point and can withstand extreme temperatures without losing its hardness or strength. This makes it suitable for use in applications that involve high heat and friction.

- Corrosion resistance: 6% tungsten carbide grade materials are also highly resistant to corrosion, making them ideal for use in harsh environments or applications where exposure to corrosive substances is common.

The Extramet Advantage

When you work with Extramet Products, LLC for your tungsten carbide machining needs, you can expect the following advantages:

- Quality materials: Extramet uses only the highest quality tungsten carbide grades, ensuring that our customers receive durable and reliable products.

- Customization options: We offer a wide range of customization options to meet your specific machining needs. Our team works closely with customers to understand their requirements and deliver tailored solutions.

- Fast turnaround time: With state-of-the-art manufacturing facilities and efficient processes, we are able to provide fast turnaround times for our customers without compromising on quality.

- Technical expertise: Our team of experts has extensive knowledge and experience in machining tungsten carbide materials. We use the latest technology and techniques to ensure precise and accurate results.

Contact Us

So if you’re looking for the best tungsten carbide machining services for 6% tungsten carbide grade materials, our team at Extramet Products, LLC is here to help. Contact us today to discuss your project and see how we can meet your machining needs with our high-quality services. We look forward to working with you!